PPS is used in a wide range of applications, including automotive, electrical, mechanical, petrochemical, pharmaceutical, light industry, military, aerospace, etc. PPS resins are also made into high performance special fiber and thin film products, which are more widely used in the field of environmental protection and clean energy.

PPS is used in auto parts

Automobile industry: headlight lamp bowl, lamp holder, socket, sensors, carburetor, intake pipe spring seat, seat, gasoline pump, water tank, water room, throttle body, thermostat, adjust motor, ignition system, stents, warm wind mouth stents, thermostat, housing, impeller, pump body pointer ring, circulating pump shell, brake brake bracket, transmission, brake locks, flow pumps, gas pumps, etc.

The application of PPS

Electrical field: electric fan, microwave holder, dryer, coffee pot, toaster, rice cooker, hot air tube, perm, air transfer vortex, etc.

PPS is used in home appliances

Electronics field: miniature electronic components encapsulation, brush, brush holder, connector, wire connector, transformer switch, small circuit boards, switches, high voltage terminal, medium wave filter, socket, lamp holder, socket connector, coil skeleton, fine-tuning capacitor, boiler sensors stents, insurance base, electronic motor, micro shield, bearing, etc.

The application of PPS

Medical devices: connectors, adapters, drug release equipment, surgical detectors, filtration systems, surgical tools, endoscopes.

Mechanical parts: pump shell, pump wheel, watt, gear, pulley, wanxiang head, sealing pad, flange, counter, level instrument, flowmeter parts, bearing cage, etc.

Aerospace: gun shell, helmet, warship submarine corrosion resistant wear parts, aircraft connector, coil frame, instrument panel.

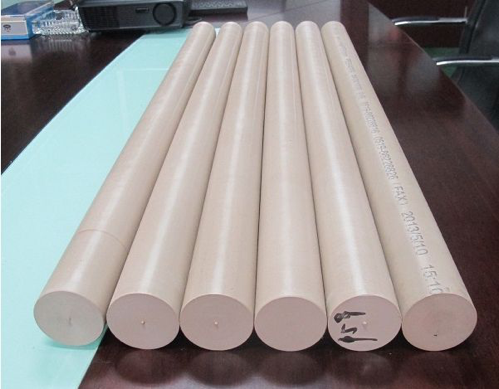

Plate and rod area: suitable for high temperature, insulation, chemical corrosion and other special environment.

Fiber field: made of high performance special fiber for high temperature flue gas and special hot medium filter material, dry belt of paper industry and cable coating and fireproof fabric.

Coating areas: because the PPS to glass, aluminum, stainless steel and so on has a very high bonding strength, highly suitable for chemical equipment lining, wear-resistant coating, metal abrasive and pipeline anti-sticking coating, titanium, steam electric iron non-stick coating, non-stick lampblack machine.